Do you have the following problems with your carbide drill bits: Wear on the outer edges, chipping of the cutting edge or tip, tool breaking? In this article we will mention the causes of most of the problems that may occur with your drill bits. To clarify, in this article we’ll be focusing on work pieces made of metals, alloys and non-ferrous materials.

We’ll see the 4 main causes for problems that you may have with your carbide drill bits.

- Speeds & Feeds

- Incompatible coolant

- Loose drill bit (Inadequate clamping)

- Wrong type of tip

The first two causes aren’t really surprising, Speeds/feeds & Coolant.

Loose drill bits (Improper clamping) this is a cause that is not necessarily solved with a better mandrel or drill chuck. Sometimes, with the addition of the bit inside your drill chuck, it is sufficient for the vibration to be eliminated or reduced considerably by reducing the exposed part of the bit. If it is not possible to insert the drill bit, you can look for short bits or simply tighten the drill bit more with a wrench or tool that allows you to give the proper support.

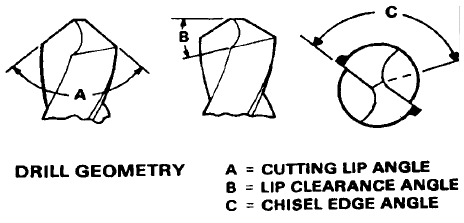

Incorrect type of drill tip: This can come from the incorrect selection of the drill bit or the incorrect sharpness of the tip. There are 3 variables in the end geometry for the different kinds of materials.

For different materials, different values of these variables are required.