In the world of manufacturing, efficient and precise machining is essential for achieving high-quality products. Machine centers play a vital role in this process, and the fixtures used within these centers are crucial for holding workpieces securely in place during machining operations. Clamping systems are commonly employed for this purpose, and three popular types are mechanical, pneumatic, and hydraulic clamping. In this article, we will explore the key differences between these clamping methods and their respective advantages and disadvantages in machine center fixtures.

- Mechanical Clamping

Mechanical clamping utilizes mechanical means to secure workpieces in place. It typically involves the use of clamps, screws, or levers to apply a physical force on the workpiece, thereby immobilizing it within the fixture. Mechanical clamps are manually operated and rely on the skills and judgment of the operator.

Advantages:

- Simplicity: Mechanical clamping systems are relatively straightforward in design and operation, making them easy to understand and implement.

- Cost-effective: Mechanical clamping solutions are generally more affordable compared to their pneumatic and hydraulic counterparts, making them a preferred choice for simpler machining operations.

- High holding force: Mechanical clamps can provide robust clamping force, ensuring excellent workpiece stability during machining processes.

Disadvantages:

- Time-consuming: Mechanical clamping requires manual operation, which can be time-consuming, especially when handling large or complex workpieces.

- Limited adaptability: Mechanical clamping systems may have limitations in terms of accommodating different workpiece sizes and shapes, requiring additional setup and adjustment time.

- Operator dependency: The effectiveness of mechanical clamping relies on the operator's skill and precision, which may introduce variability and increase the risk of human error.

- Pneumatic Clamping

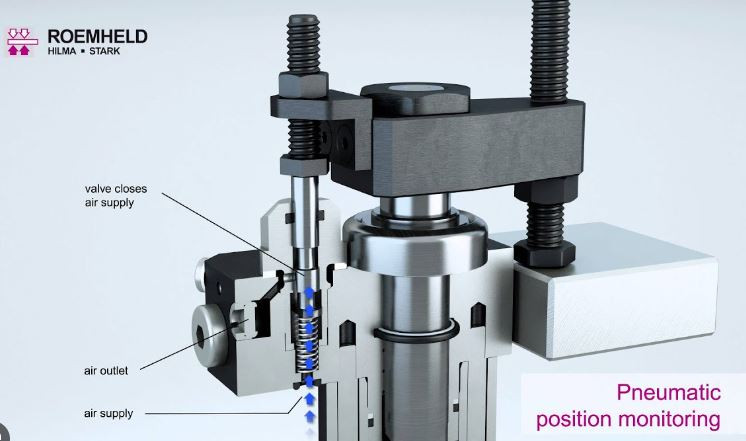

Pneumatic clamping employs compressed air to generate the clamping force required to hold workpieces securely in place. It utilizes pneumatic cylinders or air-powered clamps to apply pressure on the workpiece, creating a reliable grip within the fixture.

Advantages:

- Speed and automation: Pneumatic clamping systems offer rapid clamping and unclamping operations, reducing setup time and increasing overall productivity. They can also be integrated with automated systems, allowing for seamless operation in manufacturing lines.

- Adjustable force: Pneumatic clamps often feature adjustable pressure, enabling precise control over the clamping force applied to the workpiece.

- Enhanced adaptability: Pneumatic systems can be easily adapted to accommodate different workpiece sizes and shapes through the use of modular or adjustable components.

Disadvantages:

- Limited force capacity: Pneumatic clamping may have limitations in terms of the maximum clamping force it can provide, making it less suitable for heavy-duty machining applications.

- Sensitivity to air supply: Pneumatic systems require a reliable and consistent air supply. Any interruption or fluctuation in the air source can affect the clamping performance.

- Maintenance requirements: Pneumatic systems may necessitate regular maintenance and monitoring to prevent air leaks and ensure optimal performance.

- Hydraulic Clamping

Hydraulic clamping utilizes hydraulic fluid to generate the clamping force required to secure workpieces within the fixture. Hydraulic cylinders or hydraulic-powered clamps are employed to exert pressure on the workpiece, offering strong and reliable clamping capabilities.

Advantages:

- High clamping force: Hydraulic systems can provide substantial clamping force, making them well-suited for heavy-duty machining applications or when working with challenging materials.

- Smooth operation: Hydraulic clamps offer precise and smooth clamping and unclamping actions, contributing to improved workpiece stability and machining accuracy.

- Reduced operator effort: Hydraulic clamping systems require less manual effort compared to mechanical clamps, as they rely on hydraulic power to generate the necessary force.

Disadvantages:

- Complexity and cost: Hydraulic clamping systems are generally more complex and expensive than mechanical or pneumatic alternatives, requiring additional components such as hydraulic power units and control systems.

- Maintenance and leakage risks: Hydraulic systems need regular maintenance to ensure proper functioning and prevent leaks. Leakage can lead to environmental hazards and compromise the clamping performance.

- Safety considerations: Hydraulic systems operate at high pressures, necessitating appropriate safety measures to prevent accidents and ensure operator well-being.

Conclusion

Choosing the appropriate clamping system for machine center fixtures depends on various factors, including the nature of the machining operation, workpiece characteristics, and desired productivity. Mechanical clamping offers simplicity and affordability but may be more time-consuming and operator-dependent. Pneumatic clamping provides speed, adjustability, and adaptability, although it has limitations in terms of force capacity. Hydraulic clamping excels in heavy-duty applications, offering high force and smooth operation, but requires more complex setup and maintenance.

Ultimately, selecting the most suitable clamping method for machine center fixtures requires careful consideration of these factors, balancing the requirements of the machining process with the available resources and desired outcomes.