The performance of the drill bits depends on their design, composition and the type of material they will drill. Several factors will determine which is the most suitable drill bits according to the material, be it steel, copper, zinc, aluminum, brass, etc. This is mainly due to the characteristics that ferrous metals have, unlike non-ferrous ones.

Properties of Ferrous and Non-Ferrous Metals

Ferrous Metals

Ferrous Metals are those that contain iron. These include stainless steel, high carbon, high-speed steels and cast iron steels. Ferrous metals generally have higher tensile strength than non-ferrous metals. This feature makes them an excellent choice for construction materials, either structural or design. They are also used in industrial applications such as containers, tools and appliances. Tooling designers must take into account the hardness and tenacity of the materials when deciding which drill bit they’ll use.

Non-Ferrous Metals

Non-Ferrous metals, especially copper, lead, zinc, and brass, also occupying certain niches in the construction and manufacturing industries. They are excellent for applications where there will be moisture that would oxidize ferrous metals. They are also more malleable, conductive and can be manipulated easier in different ways. They are not magnetized so they are useful for electrical components.

The following variants are used by manufacturers of drill bits to adapt them to the different hardness and properties of the work materials:

POINT ANGLE:

The drill bit point can be altered to have more precise holes (better entry, better centered and higher quality). The 118° point angle is used as the standard angle because it adapts relatively well on most applications. This points can be used with most soft steels and non-ferrous metals. The 135° point drill bits can be used to those materials in addition to harder steels. On those harder steels, the 135° point has an advantage of being able to work with less pressure during the feed and also helping the drill bit to more easily center it.

Non-ferrous metals can be worked with greater speed and the risk of breakage is much lower. The chip of the material comes out as a spring or strings unlike small chips on the harder metals. For this, wider grooves are required to keep these longer debris from sticking. The point of the bits has a greater angle that facilitates the cutting of the drill.

FLUTES:

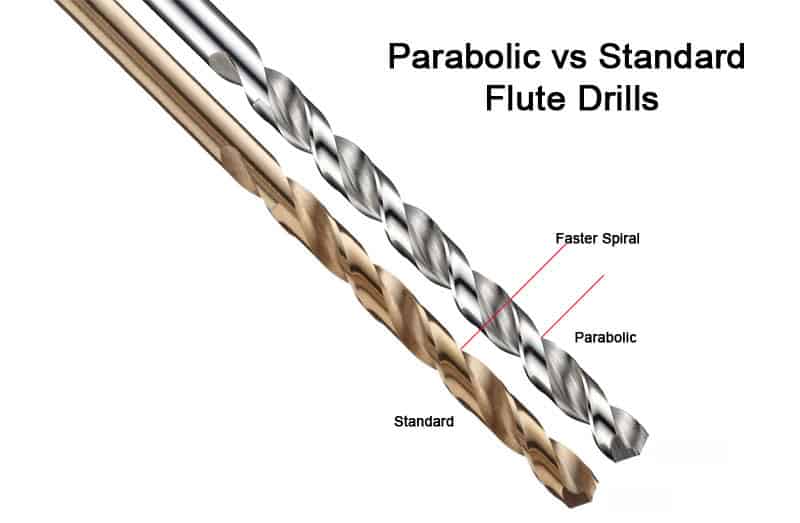

Flutes have two main purposes: 1) To remove the cut material (chips) out of the hole. 2) Allow oil/coolant to flow through the whole body of the drill bit and cool down the tool. The type of material to drill will help us determine the width and form of the flutes. Hard ferrous metals can be drilled with bits at lower speeds than what you would use with non-ferrous metals. The spiral of the flute tends to be slower since the chips are not as flexible. Also, the slower spiral, allows for greater rigidity at the tip of the drill forming a stronger angle. The result of this is that we have a smaller ship that manages to evacuate more easily.

Non-ferrous metals can be worked with greater speed and the risk of breakage is much lower. The chip of the material comes out as a spring or strings unlike small chips on the harder metals. For this, wider grooves are required to keep these longer debris from sticking. The point of the bits has a greater angle that facilitates the cutting of the drill.

CONSTRUCTION:

Harder cutting material, the harder drill bit material needed. Carbon steel doesn’t work for drilling in metals. To cut metal no matter how soft it is, one of the following is required: High Speed Steel (H.S.S.), Carbide Tip or Solid Carbide. H.S.S. is widely used due to its low cost and cutting performance on soft metals such as copper, zinc, aluminum and other non-ferrous carbon steel. By using an alloy of HSS and 5 to 8% of cobalt, you’ll have a longer lasting edge that’ll help the tool last longer. This alloy is useful for tempered steel, cast iron and some titanium alloys.

To increase the speed and wear resistance significantly, carbide drills are required. They tolerate very high temperatures and are excellent for high volume applications in stainless steel or other hard alloy parts.

For a more economical solution to solid carbide, you can use HSS drill bits with a carbide tip and they will be effective for us in non-ferrous metals and other abrasive materials.